Introduction

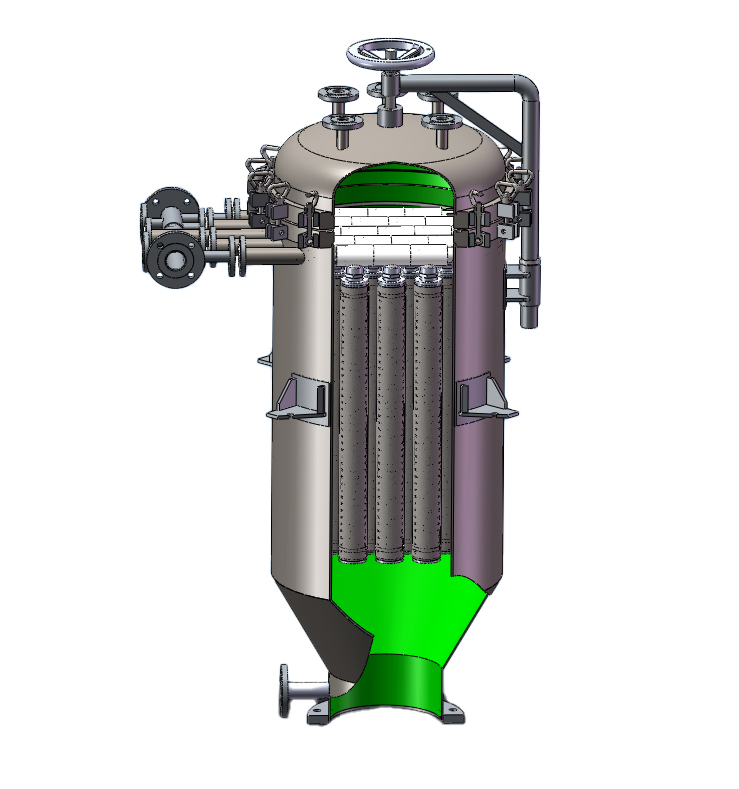

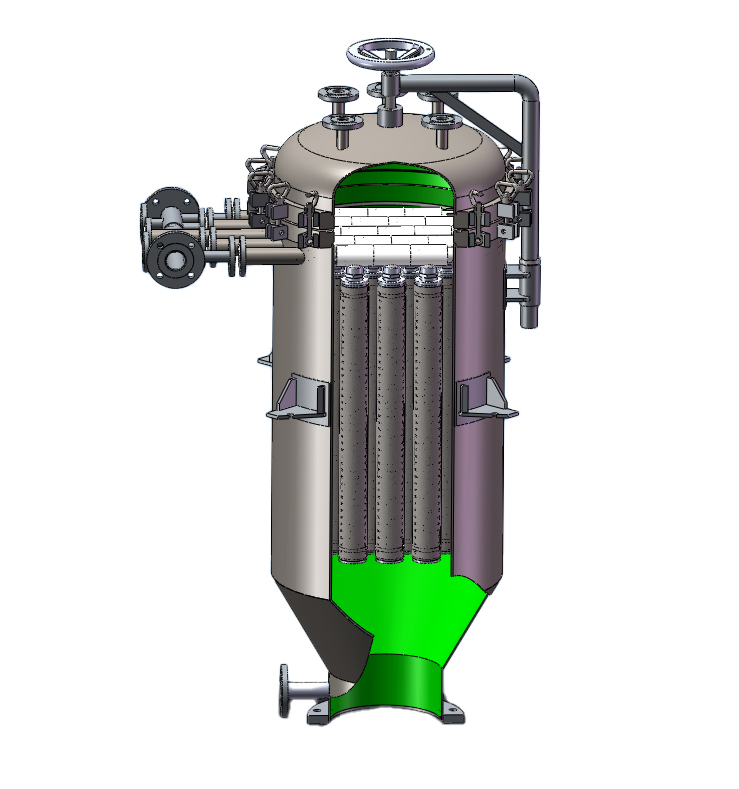

| VITHY? VZTF series Automatic Candle

Filter (also called Cake Layer Filter or Self-cleaning Filter) is a new type

of pulse-jet cleaning filter. The filter is a fine filtration equipment developed

by our R$D team based on traditional similar products. It integrates multiple

pipe filter elements inside. It 1) has a unique structure, and it is 2) small, 3)

efficient and 4) easy to operate, with 5) low filtration cost and 6) no

environmental pollution. Specifically, the filter 1) cleans the

filter elements through pulse-jetting the filter cake, 2) runs automatically in a closed environment, 3) has a large filtration area, 4) has a large dirt-holding

capacity, and 5) has wide application. The VZTF series Automatic Candle Filter has

five functions: direct filtration, pre-coating filtration, slurry

concentration, filter cake recovery, and filter cake washing. It can be applied

to various complex filtration occasions such as high solid content, viscous

liquid, ultra-high precision, and high temperature. |

Principle of Operation

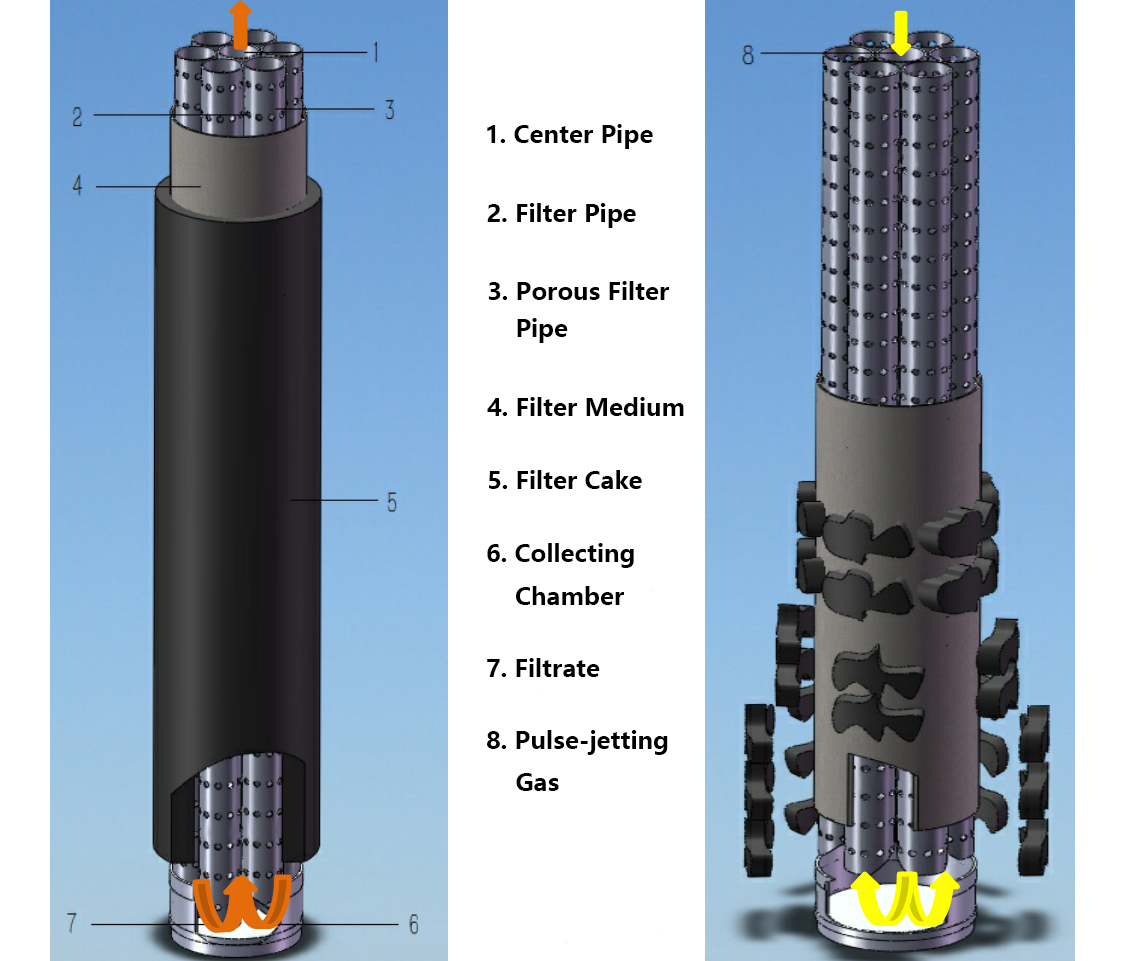

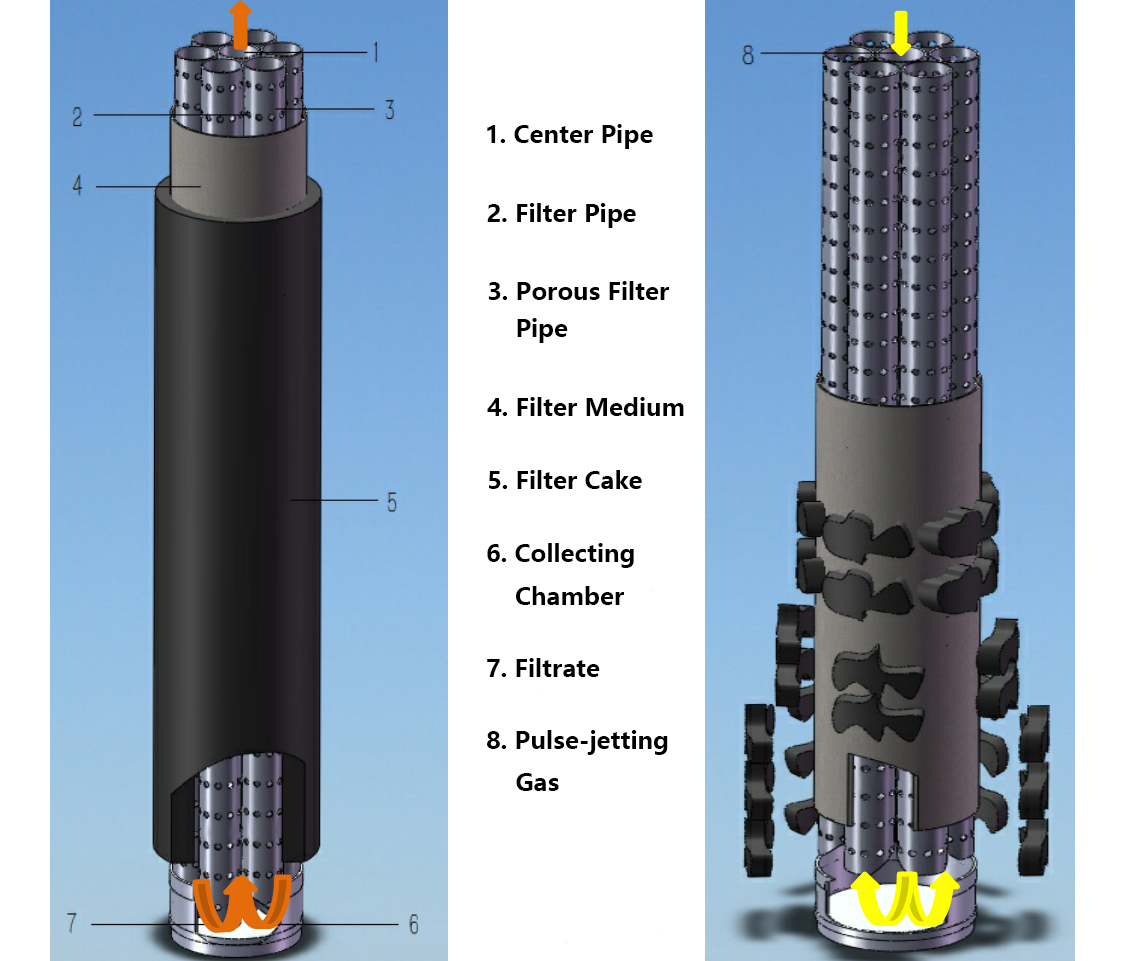

VITHY? VZTF Automatic Candle Filter integrates

multiple porous cartridges inside a sealed container. The outer surface of the

cartridge is covered with a filter cloth. When pre-filtering, the slurry is pumped

into the filter. The liquid phase of the slurry goes through the filter medium

into the center of the porous cartridge, and then collects to the filtrate outlet

and discharges. Before the filter cake forms, the discharged filtrate is

returned to the slurry inlet and sent to the filter for circulating filtration

until the filter cake forms (when the filtration requirement is met). At this

time, a signal is sent to stop the circulating filtration. The filtrate is sent

to the next process unit through a three-way valve. Then the filtration begins.

After a time, when the filter cake on the porous cartridges reaches a certain

thickness, a signal is sent to stop feeding. Then, the residual fluid inside

the filter is discharged. And a signal is sent to start pulse-jetting (with

compressed air, nitrogen, or saturated steam) to blow the filter cake off.

After a time, a signal is sent to stop pulse-jetting and open the filter residue outlet for discharging. After

discharge, the outlet is closed. The filter returns to its initial state and is

ready for the next round of filtration.

Product Features

■ Automatic control

of the whole process

■ Wide range of

applications and great filtration effect: Plum blossom-shaped cartridge

■ Smooth operation and

reliable performance

■ Low labor

intensity: Simple operation; automatically pulse-jetting to clean the filter;

automatically unloading the filter residue

■ Low cost and good

economic benefit: Filter cakes can be washed, dried, and recycled.

■ No leakage, no pollution,

and a clean environment: Airtight filter housing

■ Complete

filtration at once

Specifications

Filtration Area

| 1 m2-200 m2, larger sizes can

be customized |

Filtration Precision | 1μm -1000μm, depending on the choice of the filter

element |

Filter Element | Filter cloth (PP,

PET, PPS, PVDF, PTFE, etc.), cartridge (FRPP, PVDF, 304/316L) |

Design Pressure | 0.6MPa/1.0MPa, higher pressure can be customized |

Filter Housing Diameter | Φ300-3000, larger sizes can be customized |

Filter Housing Material | 304/316L/2205/carbon steel/plastic lining/spray coating/titanium,

etc. |

Bottom Valve | Cylinder rotation and fast flip-open, butterfly valve, etc. |

Maximum Operating Temperature (℃) | 260℃(Stainless steel cartridge: 600℃) |

Control System | Siemens PLC |

Optional Automation Instrumentation | Pressure transmitters, level sensor, flowmeter, thermometer,

etc. |

Note: The flow rate is affected by the viscosity, temperature,

filtration precision, and particle content of the liquid. For details, please

contact VITHY? engineers. |

No. | Filtration Area

(m2) | Amount of Filtration

(m3/h) | Filter Housing Volume (L) | Feed Inlet/ Filtrate Outlet Diameter

(DN) | Filter Residue Outlet Diameter (DN) | Filter Housing Diameter (mm) | Total Height

(mm) | Filter Housing Height

(mm) | Sewage Outlet Height (mm) |

1 | 1 | 2 | 140 | 25 | 150 | 458*4 | 1902 | 1448 | 500 |

2 | 2 | 4 | 220 | 32 | 150 | 458*4 | 2402 | 1948 | 500 |

3 | 3 | 6 | 280 | 40 | 200 | 558*4 | 2428 | 1974 | 500 |

4 | 4 | 8 | 400 | 40 | 200 | 608*4 | 2502 | 1868 | 500 |

5 | 6 | 12 | 560 | 50 | 250 | 708*5 | 2578 | 1944 | 500 |

6 | 10 | 18 | 740 | 65 | 300 | 808*5 | 2644 | 2010 | 500 |

7 | 12 | 26 | 1200 | 65 | 300 | 1010*5 | 2854 | 2120 | 600 |

8 | 30 | 66 | 3300 | 100 | 500 | 1112*6 | 4000 | 3240 | 600 |

9 | 40 | 88 | 5300 | 150 | 500 | 1416*8 | 4200 | 3560 | 600 |

10 | 60 | 132 | 10000 | 150 | 500 | 1820*10 | 5400 | 4500 | 600 |

11 | 80 | 150 | 12000 | 150 | 500 | 1920*10 | 6100 | 5200 | 600 |

12 | 100 | 180 | 16000 | 200 | 600 | 2024*12 | 6300 | 5400 | 800 |

13 | 150 | 240 | 20000 | 200 | 1000 | 2324*16 | 6500 | 5600 | 1200 |

Filter Cloth

No. | Name | Model | Temperature | Squashed-Width |

1 | PP | PP | 90℃ | +/-2mm |

2 | PET | PET | 130℃ |

3 | PPS | PPS | 190℃ |

4 | PVDF | PVDF | 150℃ |

5 | PTFE | PTFE | 260℃ |

6 | P84 | P84 | 240℃ |

7 | Stainless Steel | 304/316L/2205 | 650℃ |

8 | Others |

|

| |

Industry Cases

■ Filtration of

Filter Aids:

Activated carbon,

diatomite, perlite, white clay, cellulose, etc.

■ Chemical Industry:

Medical

intermediates, filtration, and recovery of catalyst, polyether polyols, PLA,

PBAT, PTA, BDO, PVC, PPS, PBSA, PBS, PGA, waste plastics, titanium dioxide,

black toner, refining biomass oil from straw, high purity alμmina, glycolide,

toluene, melamine, viscose fiber, decolorization of glyphosate, refining brine,

chlor-alkali, recovery of polysilicon silicon powder, recovery of lithium

carbonate, production of raw material for lithium battery, filtration of

solvent oils such as white oil, filtration of crude oil from oil sands, etc.

■ Pharmaceuticals

Industry:

Medical

engineering, bio-pharmaceutical industry; vitamin, antibiotic, fermentation

broth, crystal, mother liquor; decarbonization, suspension, etc.

■ Food Industry:

Saccharifing

fructose into solution, alcohol, edible oil, citric acid, lactic acid,

lycopene, decarbonization and decolorization of monosodium glutamate; yeast,

fine filtration of soy protein, etc.

■ Waste and

Circulating Water Treatment:

Heavy metal

wastewater (electroplating wastewater, wastewater from circuit board

production, hot-dip galvanizing wastewater), battery wastewater, magnetic

material wastewater, electrophoresis, etc.

■ Dewaxing,

Decolorization, and Fine Filtration of Industrial Oils:

Biodiesel,

hydraulic oil, waste oil, mixed oil, base oil, diesel, kerosene, lubricant,

transformer oil

■ Dewaxing and

Decolorization of Vegetable Oil and Edible Oil:

Crude oil, mixed

oil, peanut oil, rapeseed oil, corn oil, sunflower seed oil, soybean oil, salad

oil,mustard

oil, vegetable oil, tea oil, pressed oil, sesame oil

■ Automotive

Electronics:

Abrasive slurry,

iron mud, graphene, copper foil, circuit board, glass etching solution

■ Metallic

Mineral Smelting:

Lead, zinc, germanium,

wolfram, silver, copper, cobalt, etc.